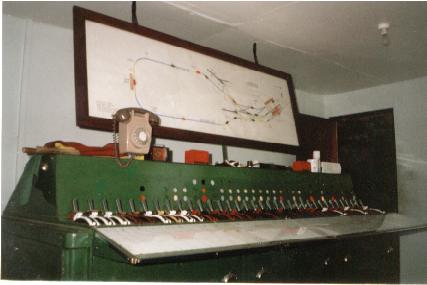

Signal Frame

The signal frame is one of the few Westinghouse Type L still in operation

and the 35 lever frame was originally part of the Gloucester Road

(Croydon) box instalation. The levers are fully interlocked with the point

detection and track circuits. Unlike the original installation the interlock

logic is not performed by interconnecting the lever switches (D-bands)

and external relays, but a custom built micro-computer is used and the

logic performed by a program stored on an EPROM. The lever positions, point

detection and track circuits are used as inputs, and outputs from the computer

drive the interlock solenoids, point motor relays, signals and the track

diagram. With the exception of the signals, which use a low voltage AC

supply, all systems run from a constantly charged 12v car battery. Although

not really in keeping with railway tradition, doing it this way means that

the system can be easily updated to meet changing track layouts. The design

also has two totally automatic modes of operation built-in which enables

the railway to function in the absence of a signalman.

Signals

The majority of signals are built using comercial vehicle marker lamp

housings running from a 12v AC supply. The approach signal to the station

complex is fitted with 12v 20w dichroic bulbs giving visibility of over

100 meters, even on sunny days. The signal at New Barn Halt (400m from

the box) is supplied with 110v from a standard industrial safety transformer.

All are operated by solid state switches in the box.

Points

The points are operated by car windscreen motors modified to give 2

stop positions. They are contolled by relays driven by the box computer.

The car battery is used to absorb the high motor currents. The point position

is detected by microswitches directly operated by the blade tie bar.

Track circuits

Unlike full size practice the track circuits are 'single ended' with

one rail permenently connected to ground. The other rail is fed with 12v

DC through a resistor and the voltage on that rail monitored electronically.

The monitor circuit is designed to deal with the intermittent rail-wheel

contact and the leakage caused by wet sleepers.

HOME